Coachwork Central Ltd started trading in 1993, mainly concentrating of Bus and coach refurbish work and

Commercial Body building.

In 1998 due to strong market pressure to fill a need in the market place for a specialist Coach-building Company, the focus turned to the manufacture of high quality coaches.

With a strong focus on customers’ needs and specialist requirements we have a flexible manufacturing

philosophy.

Our facilities and experience enable us to meet the needs and expectations of all customers.

Coachwork Central Ltd started trading in 1993, mainly concentrating of Bus and coach refurbish work and

Commercial Body building.

In 1998 due to strong market pressure to fill a need in the market place for a specialist Coach-building Company, the focus turned to the manufacture of high quality coaches.

With a strong focus on customers’ needs and specialist requirements we have a flexible manufacturing

philosophy.

Our facilities and experience enable us to meet the needs and expectations of all customers.

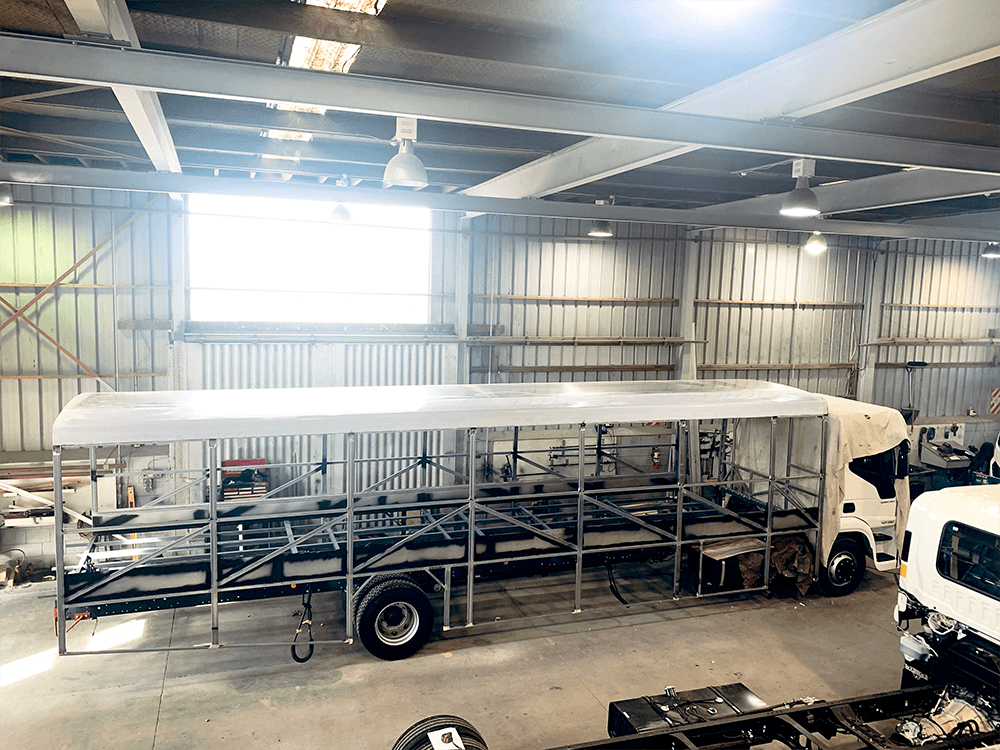

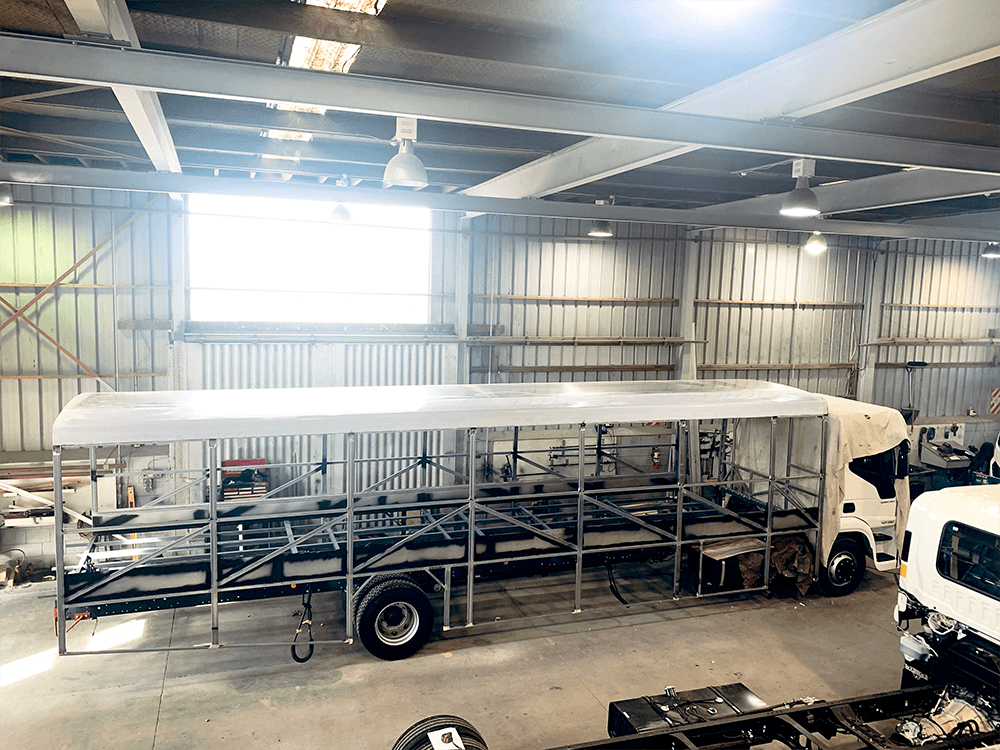

ROBUST BUT FLEXIBLE JIGS allow for designs to be tailored around each customer’s special needs. All our frames are galvanized steel primed in two pot protective systems.

LASER LEVELS AND HIGH STRENGTH STEEL combines to produce a light weight integral body to match the design parameters of modern chassis and individual customer

needs.

Attention is paid to maximum luggage area and good maintenance access.

LASER LEVELS AND HIGH STRENGTH STEEL combines to produce a light weight integral body to match the design parameters of modern chassis and individual customer

needs.

Attention is paid to maximum luggage area and good maintenance access.

PAINT FACILITIES: A heated booth designed to take the largest coaches allowed on the road now … and in the

future.

We also do minor touch-ups and full repaints in all types of paint as per the customer’s fleet specification.

QUALITY REFURBISHMENTS extend the economic life of a vehicle. Our skilled staff can handle full re-trims on-site, modern glazing systems, and interior fit outs.

We also have access to all major air conditioning suppliers’ so we can retro-fit and commission modern equipment for your customers’ comfit.

QUALITY REFURBISHMENTS extend the economic life of a vehicle. Our skilled staff can handle full re-trims on-site, modern glazing systems, and interior fit outs.

We also have access to all major air conditioning suppliers’ so we can retro-fit and commission modern equipment for your customers’ comfit.

SPARE PARTS: We are able to procure, manufacture or offer alternative parts for most Coachwork

International bodies.

Limited second-hand parts are kept to assist with minor replacement requirements.

From the first initial customer contact to the product delivery, systems are in place to ensure the customer gets what they want to the quality they expect.

© 2021 All rights reserved